Nickel-Plated Brass Automatic Check Valve

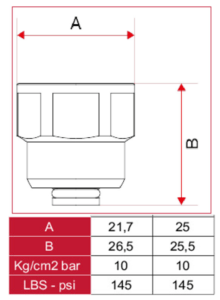

The Nickel-Plated Brass Automatic Check Valve, at 10mm (3/8″), excels in high-temperature environments up to 110°C and withstands pressures up to 10 bar (145 psi), featuring secure BSP threads for reliable, leak-proof performance in various systems.

$10.92 Inc. GST

Nickel-Plated Brass Automatic Check Valve: A Must-Have for Advanced Fluid Control

The Nickel-Plated Brass Automatic Check Valve is essential for fluid control systems, ensuring unidirectional flow and preventing backflow with its advanced design and robust construction.

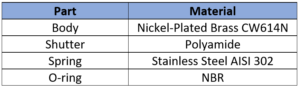

Robust Material and Design

Constructed from high-quality nickel-plated brass, it offers excellent corrosion resistance, durability, and a sleek appearance. The nickel plating enhances the valve’s longevity and performance, making it suitable for various applications, including water, oil, and gas systems.

Automatic Operation

Equipped with an automatic mechanism, this valve prevents reverse flow efficiently, safeguarding the system from contamination and damage. It operates seamlessly without manual intervention, closing promptly when backflow is detected to maintain system integrity.

Versatility and Compatibility

This valve is designed for standalone use complementing other system components like the Nickel-Plated Brass Automatic Air Vent Valve, providing a comprehensive solution for fluid control and system protection.

Key Features at a Glance

Let’s talk about the Nickel-Plated Brass Automatic Check Valve. It’s got a size of 10mm (3/8″), perfect for a range of piping setups. This valve is an exceptional performer in the heat, handling up to 110°C, so it’s great for those high-temperature applications. It has extremely robust handling pressure, up to 10 bar (145 psi). And the best part? Its Male/Female BSP threads ensure a tight, leak-free connection, giving you peace of mind about your system’s dependability.

Application Range

Ideal for a wide range of applications, from residential plumbing to industrial processes, this check valve ensures efficient and reliable flow control, making it a must-have for any system requiring precise fluid management.

The Nickel-Plated Brass Automatic Check Valve is a high-performance, durable, and reliable solution for preventing backflow and ensuring efficient system operation. Its superior construction, automatic functionality and robust specifications make it an invaluable tool for safeguarding and optimising fluid control systems.

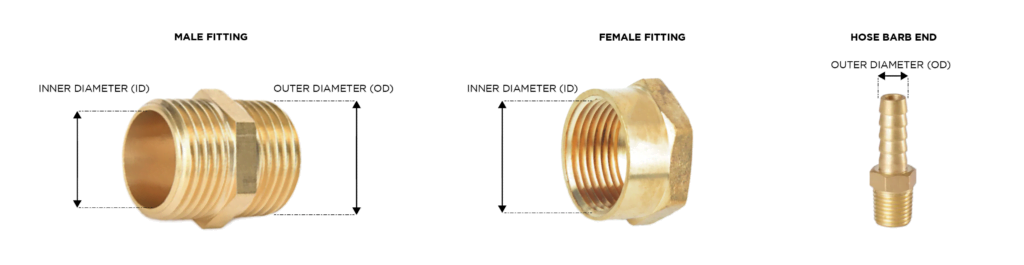

| Size | Male Fitting End | Female Fitting End | Threads Per Inch | Actual Barb End | ||

|---|---|---|---|---|---|---|

| Metric Size (mm) | Imperial Size (inch) | Inner Diameter (mm) | Outer Diameter (mm) | Inner Diameter (mm) | Outer Diameter (mm) | |

| 6 | 1/8" | 3.18 | 10.16 | 10.16 | 28 | 3.18 |

| 7 | 3/16" | 28 | 4 | |||

| 8 | 1/4" | 6.35 | 13.66 | 13.66 | 19 | 6.35 |

| 9 | 5/16" | 19 | 8 | |||

| 10 | 3/8" | 9.53 | 17.17 | 17.17 | 19 | 9.53 |

| 15 | 1/2" | 12.7 | 21.51 | 21.51 | 14 | 12.7 |

| 18 | 5/8" | 14 | 15.88 | |||

| 20 | 3/4" | 19.04 | 27 | 27 | 14 | 19.04 |

| 25 | 1" | 25.4 | 33.93 | 33.93 | 11 | 25.4 |

| 32 | 11/4" | 31.75 | 42.59 | 42.59 | 11 | 31.75 |

| 40 | 11/2" | 38.1 | 48.48 | 48.48 | 11 | 38.1 |

| 50 | 2" | 50.8 | 60.47 | 60.47 | 11 | 50.8 |

| 65 | 21/2" | 63.5 | 76.09 | 76.09 | 11 | 63.5 |

| 80 | 3" | 76.26 | 88.87 | 88.87 | 11 | 76.26 |

| 100 | 4" | 101.07 | 114.14 | 114.14 | 11 | 101.07 |

| 150 | 6" | 152 | 165.12 | 165.12 | 11 | 152 |