Butterfly Valve – Wafer – Ductile Iron – Gear Operated – 316 SS Disk – EPDM Seat – WATERMARK

The Butterfly Valve=Gear Operated features a durable ductile iron body and a 316 SS disk, engineered for precise flow control in industrial environments. Its robust gear operation ensures reliable performance across numerous pressures and temperatures.

$1,781.60 – $8,874.28 Inc. GST

Butterfly Valve – Wafer – Ductile Iron – Gear Operated – 316 Stainless Steel Disk – EPDM Seat – WATERMARK

The Butterfly Valve – Wafer – Ductile Iron – Gear Operated with a 316 Stainless Steel Disk and EPDM Seat is essential in a wide array of industries, including HVAC, water and wastewater treatment, mining and general industry. Renowned for its compact design and bubble-tight shut-off, this valve is highly valued for its exceptional regulating capabilities across various applications.

Its robust construction ensures long-term durability and reliable performance, making it a staple for simple and complex fluid management systems. The valve’s ability to operate with minimal maintenance and its streamlined design for space efficiency makes it an ideal choice for cost-effective operations.

Operational Excellence

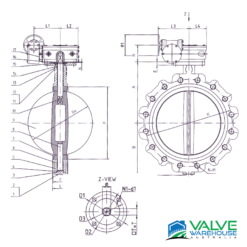

This butterfly valve features a gear-operated mechanism that ensures precise control over the flow of fluids. The gear system is designed for easy manual operation and is particularly suitable for larger valve sizes where direct lever operation would be too strenuous.

Specifications and Suitability

The valve’s body is crafted from ductile iron, coated with a blue epoxy (FBE) to withstand harsh conditions and resist corrosion. Its wafer-type setup allows for easy installation in various piping systems, with threaded metric drilled bolt holes that accommodate different setups. The design conforms to the AS 2129 Table E Australian standard, meeting rigorous safety and quality guidelines.

It can handle pressures up to 16 BAR (1600 KPA). The EPDM seat inside the valve ensures a tight and effective seal, enhancing the valve’s leak-proof. The stem of the valve is made from pinless square drive 420 stainless steel, which is exceptionally resistant to corrosion and capable of handling high flow rates without compromising the integrity of the flow path. The precision-machined 316 Stainless Steel disc perfectly aligns with the seat profile, optimising the flow and minimising wear on the liner.

Sizes available range from 350mm (14”) to 600mm (24”), covering a broad spectrum of industrial needs.

This Butterfly Valve – Wafer – Ductile Iron – Gear Operated with a 316 Stainless Steel Disk and EPDM Seat becomes a crucial investment in the efficiency and reliability of your industrial applications.

EPDM (Ethylene Propylene Diene Monomer)

- Chemical Resistance:

- Great Against Harsh Stuff: EPDM is like a superhero when it comes to resisting things like strong chemicals, weather, and sunlight. It won’t easily break down when exposed to these.

- Weak Against Oils: But it’s not so great with oils and fuels. These can make it degrade over time.

- Temperature Range:

- Handles Extreme Temperatures: EPDM works well in both very cold and very hot conditions, from -40°C to +120°C (-40°F to +248°F).

- Common Uses:

- Water and Outdoor Uses: You’ll find EPDM in car parts, heating systems, and anything that needs to be outside and withstand weather. It’s especially good for things involving water and steam.

- Durability:

- Stays Flexible and Tough: It stays bendy even in the cold and can take a bit of wear and tear.

NBR (Nitrile Butadiene Rubber)

- Chemical Resistance:

- Great Against Oils: NBR is awesome if you need something that won’t break down when it touches oil, gasoline, or similar substances.

- Weak Against Sunlight and Harsh Weather: However, it’s not as good at resisting weather and sunlight compared to EPDM.

- Temperature Range:

- Moderate Temperature Range: NBR works well in temperatures from -30°C to +100°C (-22°F to +212°F). Not as wide a range as EPDM, but still pretty good.

- Common Uses:

- Oil and Fuel Systems: You’ll often find NBR in cars and planes, especially in parts that come into contact with oil and fuel. It’s also used in industrial equipment.

- Durability:

- Tough and Flexible: NBR is tough and can handle a good amount of wear. It stays flexible, but not as well as EPDM in very cold conditions.

Summary

- EPDM is your go-to for anything that needs to resist harsh weather, chemicals, and water. Think outdoor seals and car parts.

- NBR is your best bet for things that come into contact with oil and fuel, like parts in engines and industrial machinery.

All products are covered by the full manufacturer’s warranty of 2 years. Should you have an item that is faulty we are happy to replace with a new one. Please contact us with details and/or photos of the fault as well as your contact details so we can discuss the issue and organise a replacement at our cost, or if you prefer we can provide a full refund. In some cases we may request the item be returned to us depending on the issue.