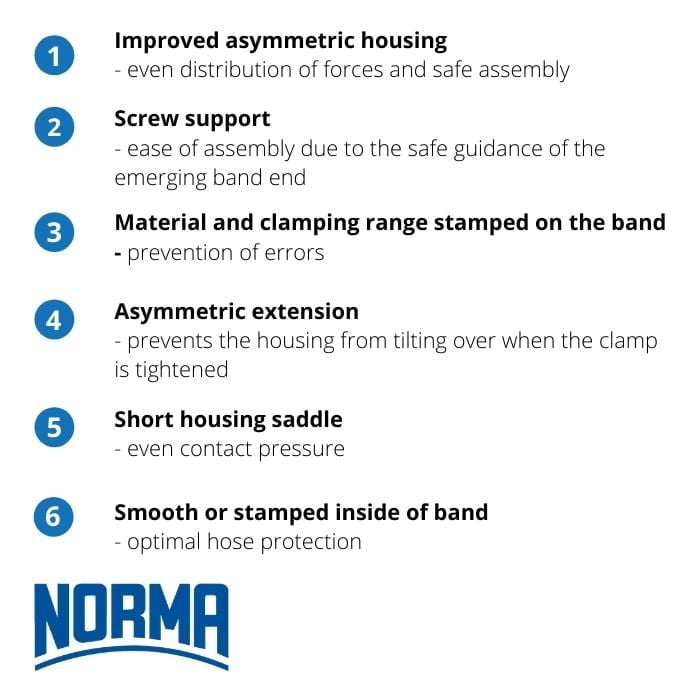

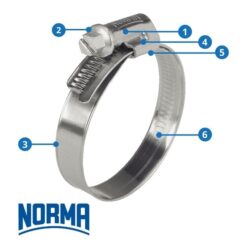

NORMA TORRO® Worm Drive Hose Clamp – W4 Full Stainless 304

The NORMA TORRO® Worm Drive Hose Clamp – W4 Full Stainless 304 offers unmatched corrosion resistance, even pressure distribution, and durability. Ideal for demanding applications, it ensures a secure, leak-proof seal with its superior construction and asymmetrical design. Perfect for diverse industrial uses.

FREEshipping on orders over $100

Buy More,SaveMore

LowPrices Guaranteed

$3.12 – $965.80 Inc. GST

Spend $200, get10%off

Spend $300, get15%off

Spend $400, get20%off

Note: Items on sale are exempt from additional discounts.