NORMA TORRO® Worm Drive Hose Clamp – W3 Full Stainless 430

The NORMA TORRO® Worm Drive Hose Clamp – W3 Full Stainless 430, with its full stainless steel construction, offers unmatched strength, corrosion resistance, and even pressure distribution, making it ideal for high-load applications across various industries.

$2.54 – $2,081.20 Inc. GST

NORMA TORRO® Worm Drive Hose Clamp – W3 Full Stainless 430

The NORMA TORRO® Worm Drive Hose Clamp with W3 full stainless steel AISI 430 construction sets the standard for durability and reliability in high-load applications. This advanced clamp design is a staple in modern engineering, offering unparalleled strength and even clamping pressure distribution. The unique asymmetrical housing ensures superior torque and aligns perfectly with the hose for optimal sealing.

Key Features:

Asymmetrical Housing:

-

- Delivers high clamping force, superior torque, and even pressure distribution.

Stainless Steel AISI 430:

-

- All components are made from this durable material, offering excellent corrosion resistance.

Multi-Range Compatibility:

-

- Adaptable across various diameters, from 8-12 mm to 280-300 mm, in accordance with DIN 3017.

Environmentally Friendly:

- Free from chromium (VI) coatings, ensuring safety and non-toxicity.

Applications:

- Joining Cooling Water Lines.

- Pressurised and depressurised fuel lines and ventilation systems.

- Oil lines, sanitary applications, and machine building applications.

- Household appliances, commercial vehicles, and more, where a secure and leak-proof seal is critical.

All this points to the unmistakable fact that this multi-range Hose Clamp is an essential tool for professionals and DIY enthusiasts alike, offering a robust solution for securing hoses in a wide range of environments. Its superior materials and construction make it ideally suited for demanding applications, ensuring reliability and performance that you can trust.

Embrace the optimal sealing capability and unmatched durability of the NORMA TORRO® Worm Drive Hose Clamp for your next project. Its wide application range and environmental safety make it versatile for any setting requiring secure hose connections.

| Band Width | Part Number | Clamping Range (mm) | W1 Alu-zinc band M/Steel Housing & Hex Screw | W2 Stainless Steel Band 1.4016 M/Steel Housing & Screw | W3 All Stainless Steel 1.4016 (430) | W4 All Stainless Steel 1.4301 (304) | W5 All Stainless Steel 1.4401 (316) |

|---|---|---|---|---|---|---|---|

| 7.5 | 8-12/7.5P | 8-12mm | ✓ | ✓ | |||

| 7.5 | 10-16/7.5P | 10-16mm | ✓ | ✓ | |||

| 9 | 8-12/9P | 8-12mm | ✓ | ||||

| 9 | 8-16/9P | 8-16mm | ✓ | ✓ | ✓ | ||

| 9 | 10-16/9P | 10-16mm | ✓ | ||||

| 9 | 12-20/9P | 12-20mm | ✓ | ✓ | ✓ | ✓ | |

| 9 | 12-22/9P | 12-22mm | ✓ | ✓ | |||

| 9 | 16-25/9P | 16-27mm | ✓ | ✓ | ✓ | ||

| 9 | 20-32/9P | 20-32mm | ✓ | ✓ | ✓ | ||

| 9 | 25-40/9P | 25-40mm | ✓ | ✓ | ✓ | ||

| 9 | 30-45/9P | 30-45mm | ✓ | ✓ | ✓ | ||

| 9 | 32-50/9P | 35-50mm | ✓ | ✓ | ✓ | ||

| 9 | 40-60/9P | 40-60mm | ✓ | ✓ | ✓ | ||

| 9 | 50-70/9P | 50-70mm | ✓ | ✓ | ✓ | ||

| 9 | 60-80/9P | 60-80mm | ✓ | ✓ | ✓ | ||

| 9 | 70-90/9P | 70-90mm | ✓ | ✓ | ✓ | ||

| 9 | 80-100/9P | 80-100mm | ✓ | ✓ | ✓ | ||

| 9 | 90-110/9P | 90-110mm | ✓ | ✓ | ✓ | ||

| 12 | 16-27/12P | 100-120mm | ✓ | ✓ | ✓ | ||

| 12 | 20-32/12P | 110-130mm | ✓ | ✓ | ✓ | ✓ | |

| 12 | 25-40/12P | 120-140mm | ✓ | ✓ | ✓ | ✓ | |

| 12 | 30-45/12P | 130-150mm | ✓ | ✓ | ✓ | ✓ | |

| 12 | 35-50/12P | 140-160mm | ✓ | ✓ | ✓ | ✓ | |

| 12 | 40-60/12P | 150-170mm | ✓ | ✓ | ✓ | ✓ | |

| 12 | 50-70/12P | 160-180mm | ✓ | ✓ | ✓ | ✓ | |

| 12 | 60-80/12P | 170-190mm | ✓ | ✓ | ✓ | ✓ | |

| 12 | 70-90/12P | 180-200mm | ✓ | ✓ | ✓ | ✓ | |

| 12 | 80-100/12P | 190-210mm | ✓ | ✓ | ✓ | ✓ | |

| 12 | 90-110/12P | 200-220mm | ✓ | ✓ | ✓ | ✓ | |

| 12 | 100-120/12P | 210-230mm | ✓ | ✓ | ✓ | ✓ | |

| 12 | 110-130/12P | 230-250mm | ✓ | ✓ | ✓ | ✓ | |

| 12 | 120-140/12P | 260-280mm | ✓ | ✓ | ✓ | ✓ | |

| 12 | 130-150/12P | 280-300mm | ✓ | ✓ | ✓ | ✓ | |

| 12 | 140-160/12P | 140-160mm | ✓ | ✓ | ✓ | ✓ | |

| 12 | 150-170/12P | 150-170mm | ✓ | ✓ | ✓ | ✓ | |

| 12 | 160-180/12P | 160-180mm | ✓ | ✓ | ✓ | ✓ | |

| 12 | 170-190/12P | 170-190mm | ✓ | ||||

| 12 | 180-200/12P | 180-200mm | ✓ | ✓ | |||

| 12 | 190-210/12P | 190-210mm | ✓ | ||||

| 12 | 200-220/12P | 200-220mm | ✓ | ||||

| 12 | 210-230/12P | 210-230mm | ✓ | ✓ | |||

| 12 | 230-250/12P | 230-250mm | ✓ | ✓ | |||

| 12 | 260-280/12P | 260-280mm | ✓ | ✓ | |||

| 12 | 280-300/12P | 280-300mm | ✓ | ✓ |

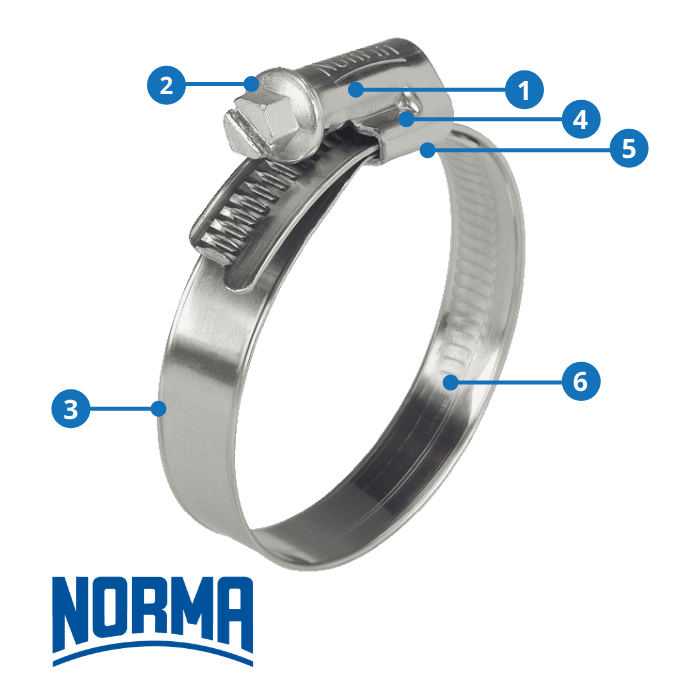

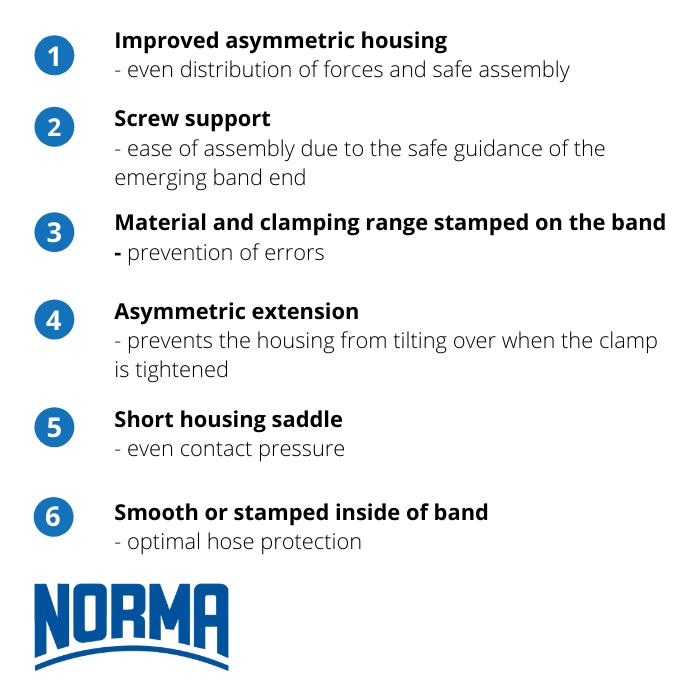

1. Improved asymmetric housing

– even distribution of forces and safe assembly

2. Screw support

– ease of assembly due to the safe guidance of the emerging band end

3. Material and clamping range stamped on the band

– prevention of errors

4. Asymmetric extension

– prevents the housing from tilting over when the clamp is tightened

5. Short housing saddle

– even contact pressure

6. Smooth or stamped inside of band

– optimal hose protection

| Size | 10-16mm/7.5, 100-120mm/12, 110-130mm/12, 12-20mm/9, 120-140mm/12, 130-150mm/12, 140-160mm/12, 150-170mm/12, 16-27mm/12, 160-180mm/12, 180-200mm/12, 20-32mm/12, 210-230mm/12, 230-250mm/12, 25-40mm/12, 260-280mm/12, 280-300mm/12, 30-45mm/12, 35-50mm/12, 40-60mm/12, 50-70mm/12, 60-80mm/12, 70-90mm/12, 8-12mm/7.5, 8-16mm/9, 80-100mm/12, 90-110mm/12 |

|---|---|

| Pack | 1, 5, 10, 25, 50, 100 |

| Material | Stainless Steel |

| Fitting Type | Clamps |

Related products

Shipping