Banjo Polypropylene Female Thread x Hose Tail

The Banjo Polypropylene Female Thread x Hose Tail fitting excels in durability and chemical resistance, making it essential for agriculture, industry, and marine use, ensuring reliable, leak-proof connections in even the most demanding environments.

$7.13 – $8.91 Inc. GST

The Banjo Polypropylene Female Thread x Hose Tail

Discover the reliability and versatility of the Banjo Polypropylene Female Thread x Hose Tail, an essential component for industrial, agricultural, and residential fluid transfer applications. Its robust design and chemical-resistant properties ensure dependable fluid connections in diverse environments.

Diverse Applications

This fitting finds extensive use across various fields, from agriculture to industrial settings. In agriculture, it’s vital for distributing water and applying chemicals like pesticides and fertilizers. Its chemical resistance ensures durability even when exposed to harsh substances. Industrial applications benefit from its ability to transfer aggressive chemicals, making it ideal for water treatment, marine applications, and more.

Key Features and Longevity

Constructed from glass-reinforced polypropylene, this fitting offers excellent strength while remaining lightweight, facilitating easy handling and installation. Its non-corrosive nature extends the lifespan of the fittings under varied environmental conditions, providing longer service life without degradation. Unlike metal alternatives, polypropylene resists rust and corrosion, ensuring durability.

Economical and Efficient

The Female Thread x Hose Tail fitting is not only durable but also cost-effective, offering a budget-friendly option without compromising quality or performance. It ensures a leak-proof connection, enhancing system integrity and preventing environmental contamination. Installation is straightforward, requiring no special tools or extensive labor, making it advantageous for both temporary setups and permanent installations.

Wide Range of Applications

With a size range accommodating diameters from 20mm to 25mm and capable of withstanding pressures up to 300 psi, this Banjo Polypropylene Female Thread x Hose Tail fitting meets the demands of a wide range of applications. Its heavy-duty build quality and excellent chemical resistance make it a smart choice for anyone looking for dependable and efficient fluid-handling solutions.

| Size | Male Fitting End | Female Fitting End | Threads Per Inch | Actual Barb End | ||

|---|---|---|---|---|---|---|

| Metric Size (mm) | Imperial Size (inch) | Inner Diameter (mm) | Outer Diameter (mm) | Inner Diameter (mm) | Outer Diameter (mm) | |

| 6 | 1/8" | 3.18 | 10.16 | 10.16 | 28 | 3.18 |

| 7 | 3/16" | 28 | 4 | |||

| 8 | 1/4" | 6.35 | 13.66 | 13.66 | 19 | 6.35 |

| 9 | 5/16" | 19 | 8 | |||

| 10 | 3/8" | 9.53 | 17.17 | 17.17 | 19 | 9.53 |

| 15 | 1/2" | 12.7 | 21.51 | 21.51 | 14 | 12.7 |

| 18 | 5/8" | 14 | 15.88 | |||

| 20 | 3/4" | 19.04 | 27 | 27 | 14 | 19.04 |

| 25 | 1" | 25.4 | 33.93 | 33.93 | 11 | 25.4 |

| 32 | 11/4" | 31.75 | 42.59 | 42.59 | 11 | 31.75 |

| 40 | 11/2" | 38.1 | 48.48 | 48.48 | 11 | 38.1 |

| 50 | 2" | 50.8 | 60.47 | 60.47 | 11 | 50.8 |

| 65 | 21/2" | 63.5 | 76.09 | 76.09 | 11 | 63.5 |

| 80 | 3" | 76.26 | 88.87 | 88.87 | 11 | 76.26 |

| 100 | 4" | 101.07 | 114.14 | 114.14 | 11 | 101.07 |

| 150 | 6" | 152 | 165.12 | 165.12 | 11 | 152 |

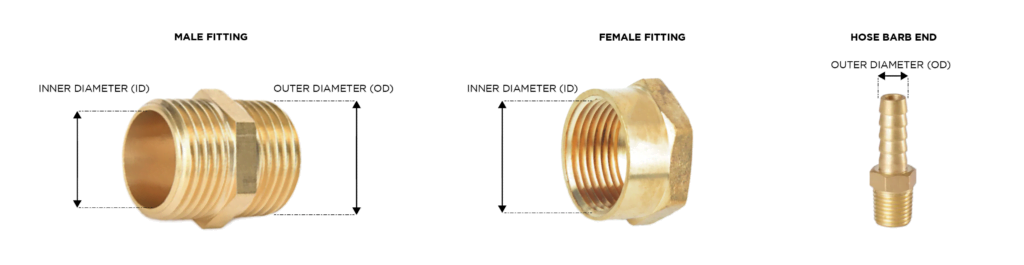

Column Definitions:

Size (Imperial): Size designated to match the ID of Fitting in inches

Size (Metric): Size designated to match the ID of Fitting in mm

Male Thread ID (mm): The actual Inside diameter of the Male Fitting in millimetres.

Male Thread OD (mm): The actual outside diameter of the Male Fitting in millimetres

Female Thread ID (mm): The actual Inside diameter of the Female Fitting in millimetres.

Actual Barb OD (mm): The actual outside diameter of the Barbed fitting in millimetres.