Brass Barbed Tee

The Brass Barbed Tee combines durability with functionality, expertly crafted from corrosion-resistant brass to ensure reliable, leak-proof connections in diverse fluid systems—from domestic water lines to industrial pneumatic networks, making it indispensable for efficient fluid management.

$7.54 – $43.79 Inc. GST

Brass Barbed Tee: Essential for Efficient Fluid Management

Robust Construction and Reliability

The Brass Barbed Tee is crafted with precision to meet the high demands of various fluid systems, making it an indispensable component in plumbing, pneumatic, and fuel systems. Made from brass, this fitting boasts exceptional corrosion resistance and can endure high temperatures, enhancing its durability. The robust nature of brass ensures that the barbed tee remains reliable across a broad range of applications, providing a steadfast solution for directing fluid or gas flow.

Design and Functionality

Characterized by its three-way connectivity, this Tee is designed to either combine or divide the flow of fluids efficiently. This makes it particularly valuable in systems where a single fluid source needs to be distributed to multiple areas or where multiple streams converge into one. Its barbed ends are meticulously engineered to secure hose connections, preventing any leakage and ensuring a continuous, uninterrupted flow. The barbs are designed to grip inside the hoses firmly, making this tee fitting a preferred choice for both permanent installations and temporary setups.

Applications and Versatility

The tee’s versatility shines in its wide range of applications. It is commonly employed in water supply lines where it aids in distributing water to various outlets without compromise. In pneumatic systems, it manages air distribution with ease, and in fuel lines, it ensures a secure passage of fuel, preventing any potential leaks and hazards. The ease of installation and removal adds to its utility, making it a go-to choice for systems requiring frequent modifications.

Specifications and Installation

Available in a variety of sizes, ranging from 7mm (3/16″) to 25mm (1″), this tee is designed to fit the internal diameter (ID) of hoses. This size range accommodates a broad spectrum of hoses and requirements, making it suitable for a diverse array of fluid handling scenarios. Its compatibility with air, water, and other fluids underlines its adaptability to different environments, further asserting its necessity in both industrial and domestic settings.

The Brass Barbed Tee stands out as a critical fitting in the landscape of fluid management. Its strong build, leak-proof design, and ease of use not only streamline the installation process but also ensure long-term reliability and performance. Whether you’re setting up a new system or upgrading an existing one, this barbed tee proves to be an essential component that enhances the efficiency and safety of your fluid handling applications.

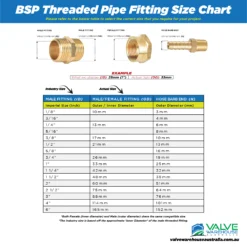

| Size | Male Fitting End | Female Fitting End | Threads Per Inch | Actual Barb End | ||

|---|---|---|---|---|---|---|

| Metric Size (mm) | Imperial Size (inch) | Inner Diameter (mm) | Outer Diameter (mm) | Inner Diameter (mm) | Outer Diameter (mm) | |

| 6 | 1/8" | 3.18 | 10.16 | 10.16 | 28 | 3.18 |

| 7 | 3/16" | 28 | 4 | |||

| 8 | 1/4" | 6.35 | 13.66 | 13.66 | 19 | 6.35 |

| 9 | 5/16" | 19 | 8 | |||

| 10 | 3/8" | 9.53 | 17.17 | 17.17 | 19 | 9.53 |

| 15 | 1/2" | 12.7 | 21.51 | 21.51 | 14 | 12.7 |

| 18 | 5/8" | 14 | 15.88 | |||

| 20 | 3/4" | 19.04 | 27 | 27 | 14 | 19.04 |

| 25 | 1" | 25.4 | 33.93 | 33.93 | 11 | 25.4 |

| 32 | 11/4" | 31.75 | 42.59 | 42.59 | 11 | 31.75 |

| 40 | 11/2" | 38.1 | 48.48 | 48.48 | 11 | 38.1 |

| 50 | 2" | 50.8 | 60.47 | 60.47 | 11 | 50.8 |

| 65 | 21/2" | 63.5 | 76.09 | 76.09 | 11 | 63.5 |

| 80 | 3" | 76.26 | 88.87 | 88.87 | 11 | 76.26 |

| 100 | 4" | 101.07 | 114.14 | 114.14 | 11 | 101.07 |

| 150 | 6" | 152 | 165.12 | 165.12 | 11 | 152 |

Column Definitions:

Size (Imperial): Size designated to match the ID of Fitting in inches

Size (Metric): Size designated to match the ID of Fitting in mm

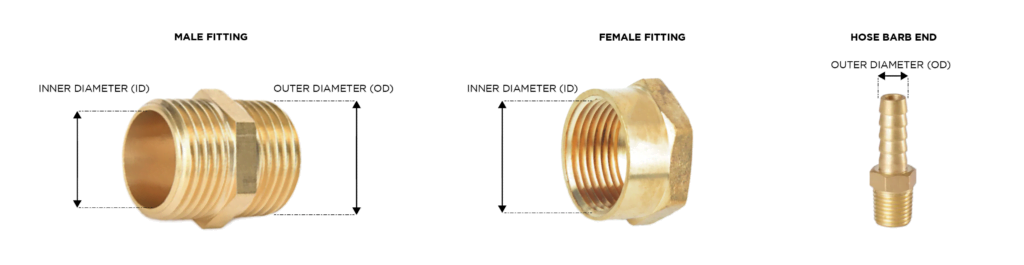

Male Thread ID (mm): The actual Inside diameter of the Male Fitting in millimetres.

Male Thread OD (mm): The actual outside diameter of the Male Fitting in millimetres

Female Thread ID (mm): The actual Inside diameter of the Female Fitting in millimetres.

Actual Barb OD (mm): The actual outside diameter of the Barbed fitting in millimetres.