Compound Pressure Gauge – 100mm Liquid Filled Dial – Bottom Entry

Experience reliable and accurate pressure measurement with our high-quality compound pressure gauge. Designed to withstand both positive and negative pressure, this stainless steel gauge, filled with glycerine, provides clear dual-scale readings and is accredited by CE, ISO 9001 and TUV.

$53.95 Inc. GST

Our high-quality liquid-filled compound pressure gauge is perfect for measuring systems that exert both positive and negative pressure on the gauge. With a pressure range of -100 kPa (-15 psi) to +150 kPa (22 psi), this gauge is versatile and reliable.

The body of the gauge is made of stainless steel, ensuring durability and longevity. It is designed with a dual-scale display, allowing for measurements in both kPa and psi. The gauge is filled with glycerine, which helps to dampen any fluctuations in pressure, resulting in accurate readings.

The connection of the gauge is 3/8 BSP bottom entry, providing a secure and reliable connection to the system being measured. Additionally, the gauge is accredited by CE, ISO 9001, and TUV, ensuring that it meets the highest quality standards.

- 100mm diameter Dial / Face

- Bottom Entry with 10mm (3/8″) Brass Tapered BSP Thread

- Glycerine Filled

- Stainless Steel Case

- Application: Pressure measurement in water lines, pumps and most general applications

It is important to note that this compound pressure gauge is specifically designed for measuring specific types of pressure. Using a simple pressure or vacuum gauge for a system that requires a compound gauge can result in damage to the gauge. Negative pressure exerted on a pressure gauge or positive pressure exerted on a vacuum gauge can cause harm to the gauge.

Our EVF pressure gauges have a proven track record of reliability and efficiency since 1991. We strive to offer our products at a competitive price, without compromising on quality.

The model range for our compound pressure gauge is COMLF100–100-150, covering a range of -100 to +150 kPa. The size of the gauge is 100mm (4) and it has an accuracy of +/- 2.5%. The work pressure is 3/4 of the full scale, fluctuating pressure is 2/3 of the full scale, and short-time pressure is the full scale of the gauge.

The operating temperature range for the gauge is -10°C to 60°C, making it suitable for a variety of environments. It is compatible with both gases and liquids, expanding its versatility. The housing of the gauge is made of 304 stainless steel, ensuring durability and protection. The window is made of polycarbonate, providing clear visibility of the gauge readings.

| kPa | PSI | BAR |

| 100 | 15 | 1 |

| 200 | 29 | 2 |

| 300 | 44 | 3 |

| 400 | 58 | 4 |

| 500 | 73 | 5 |

| 600 | 87 | 6 |

| 700 | 102 | 7 |

| 800 | 116 | 8 |

| 900 | 131 | 9 |

| 1000 | 145 | 10 |

| 1100 | 160 | 11 |

| 1200 | 174 | 12 |

| 1300 | 189 | 13 |

| 1400 | 203 | 14 |

| 1500 | 218 | 15 |

| 1600 | 232 | 16 |

| 1700 | 247 | 17 |

| 1800 | 261 | 18 |

| 1900 | 276 | 19 |

| 200 | 290 | 20 |

| 2100 | 305 | 21 |

| 2200 | 319 | 22 |

| 2300 | 334 | 23 |

| 2400 | 348 | 24 |

| 2500 | 363 | 25 |

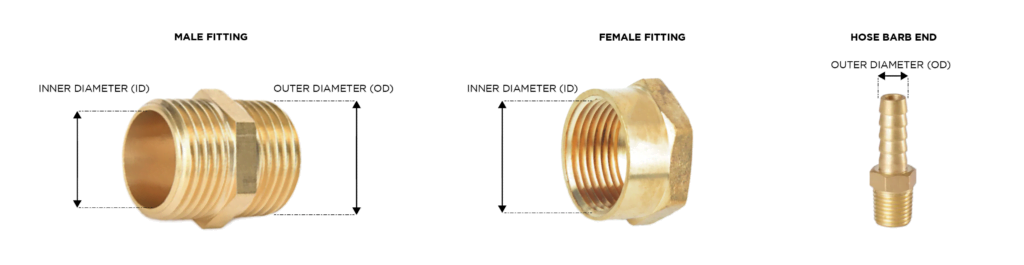

| Size | Male Fitting End | Female Fitting End | Threads Per Inch | Actual Barb End | ||

|---|---|---|---|---|---|---|

| Metric Size (mm) | Imperial Size (inch) | Inner Diameter (mm) | Outer Diameter (mm) | Inner Diameter (mm) | Outer Diameter (mm) | |

| 6 | 1/8" | 3.18 | 10.16 | 10.16 | 28 | 3.18 |

| 7 | 3/16" | 28 | 4 | |||

| 8 | 1/4" | 6.35 | 13.66 | 13.66 | 19 | 6.35 |

| 9 | 5/16" | 19 | 8 | |||

| 10 | 3/8" | 9.53 | 17.17 | 17.17 | 19 | 9.53 |

| 15 | 1/2" | 12.7 | 21.51 | 21.51 | 14 | 12.7 |

| 18 | 5/8" | 14 | 15.88 | |||

| 20 | 3/4" | 19.04 | 27 | 27 | 14 | 19.04 |

| 25 | 1" | 25.4 | 33.93 | 33.93 | 11 | 25.4 |

| 32 | 11/4" | 31.75 | 42.59 | 42.59 | 11 | 31.75 |

| 40 | 11/2" | 38.1 | 48.48 | 48.48 | 11 | 38.1 |

| 50 | 2" | 50.8 | 60.47 | 60.47 | 11 | 50.8 |

| 65 | 21/2" | 63.5 | 76.09 | 76.09 | 11 | 63.5 |

| 80 | 3" | 76.26 | 88.87 | 88.87 | 11 | 76.26 |

| 100 | 4" | 101.07 | 114.14 | 114.14 | 11 | 101.07 |

| 150 | 6" | 152 | 165.12 | 165.12 | 11 | 152 |

With a bourdon tube and movement made of copper alloy, the gauge is designed for accurate and reliable measurements. The connection is brass and the thread is BSP, ensuring a secure and leak-free connection. The scale of the gauge is dual, displaying measurements in both kPa and psi.

In conclusion, our liquid-filled compound pressure gauge offers a range of features and specifications that make it suitable for a variety of applications. Its high-quality construction, reliable measurements, and easy-to-read display make it an essential tool for any system that requires accurate pressure monitoring.

Related products

Shipping

Shipping